Components, materials, or technologies are increasingly disappearing from the market – a reality affecting many industries. Companies that are unprepared risk delays, added costs, or even production downtime.

With our Risk & Obsolescence Module, you can identify affected components early and initiate countermeasures. Whether it’s change notifications (PCNs), product discontinuations, or compliance risks – you have everything in view, centrally within your PLM system.

Your benefits with our Risk & Obsolescence Module:

Act early rather than react late – so risks don’t become real problems

What happens if your most important raw material supplier suddenly drops out?

Geopolitical crises, natural disasters, pandemics, or volatile markets – risks can’t be avoided, but you can prepare for them.

With Nexpirit and Teamcenter® PLM, you assess risks systematically and create real options for action.

We support you in turning uncertainty into manageable risk, data-driven, traceable, and integrated into your existing systems.

Many companies still track component availability manually or with isolated tools. But what happens when PCNs can’t be clearly matched to your components?

We integrate all relevant obsolescence data directly into your Teamcenter® PLM:

This way, you can evaluate risks early in the product lifecycle and make well-informed decisions.

“Many companies struggle to keep track of product changes while integrating them cleanly into their processes. Our solution addresses exactly that: component-based, transparent, and directly in PLM – so all stakeholders can make early and informed decisions.”

Lucas Dann, Managing Director Nexpirit GmbH

SiliconExpert is one of the world’s leading providers of component data – with millions of electronic and electromechanical components in its database. We bring that information where you need it: into your PLM-System.

With SiliconExpert you get:

Already using another database provider? No problem – we also integrate Z2Data, Supplyframe, or your existing provider seamlessly into your system.

Depending on your needs, we analyze risks on two levels:

And prepare for potential risks – we’ll show you how.

Obsolescence management means identifying and actively managing risks from outdated, discontinued, or unavailable components at an early stage. Components, materials, or substances are constantly subject to change – whether due to new regulations, technological advancements, or supply bottlenecks.

Professional obsolescence management helps safeguard your product development proactively:

You avoid unplanned production stops

You increase delivery reliability

You keep your bills of materials and products compliant and marketable over the long term

Tools like our Risk & Obsolescence Module in Teamcenter® help you maintain constant visibility into the status of your components. This allows you to act early – before a risk becomes a problem.

Without systematic obsolescence management, companies risk suddenly facing unavailable components. The consequences:

You receive up-to-date data on availability, discontinuations, and alternatives – directly visible in your bill of materials in PLM.

No, mechanical or software-related components can also be integrated – depending on the data source.

Depending on your system setup – initial evaluations are often possible within a few days.

Because risks don’t occur in isolation – they affect bills of materials, supply chains, and product structures. In PLM, you have all relevant info centrally collected.

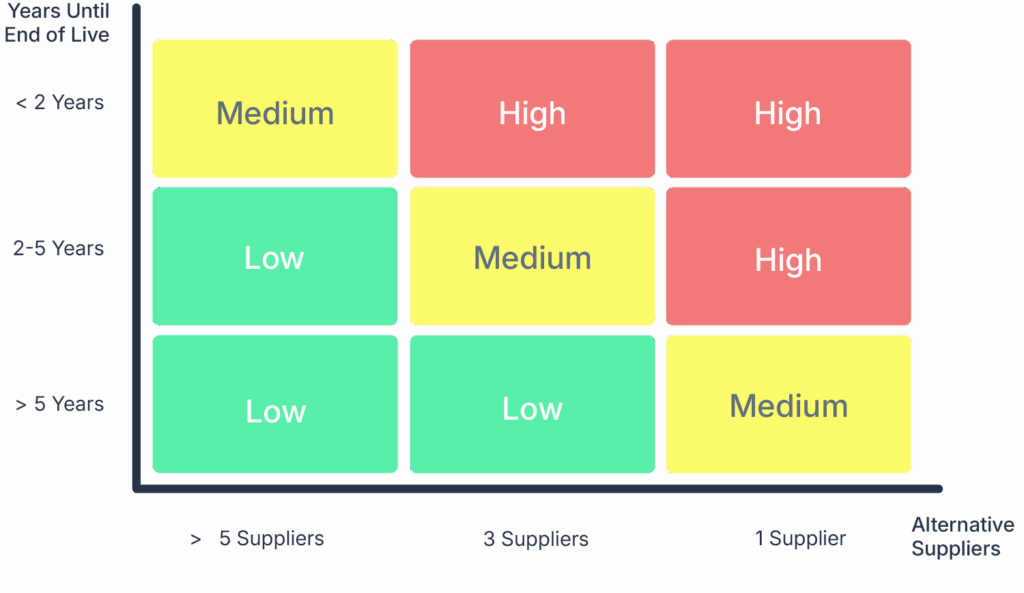

We analyze factors such as supplier dependencies, part availability, political stability, market developments and compliance requirements.

Thanks to integration with databases like SiliconExpert, you work with real-time data – including early warning indicators.

No – small and mid-sized companies in particular benefit from better oversight, planning, and the ability to act in times of crisis.

After an initial Workshop and implementation, first results are often available within just a few weeks.

With our newsletter, you’ll regularly receive insights, event tips, and expert articles directly in your inbox.

*By submitting the form, the data you provide will be processed by Nexpirit GmbH, Lohbach 8, 32457 Porta Westfalica, Germany, for the purpose of processing your enquiry(s). Your data will be processed strictly for the intended purpose. Further information on the processing of your data within our website can be found in our data protection information.