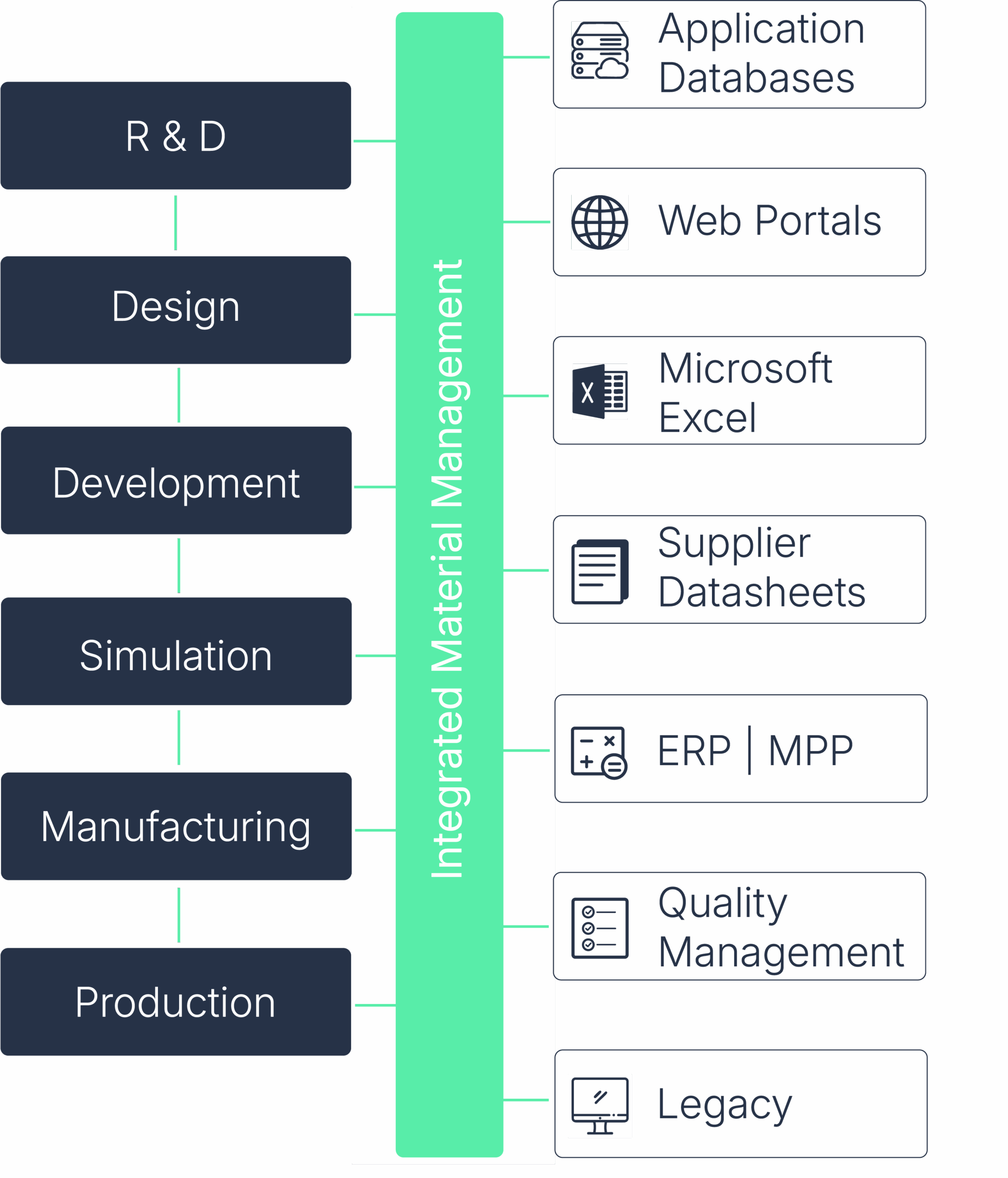

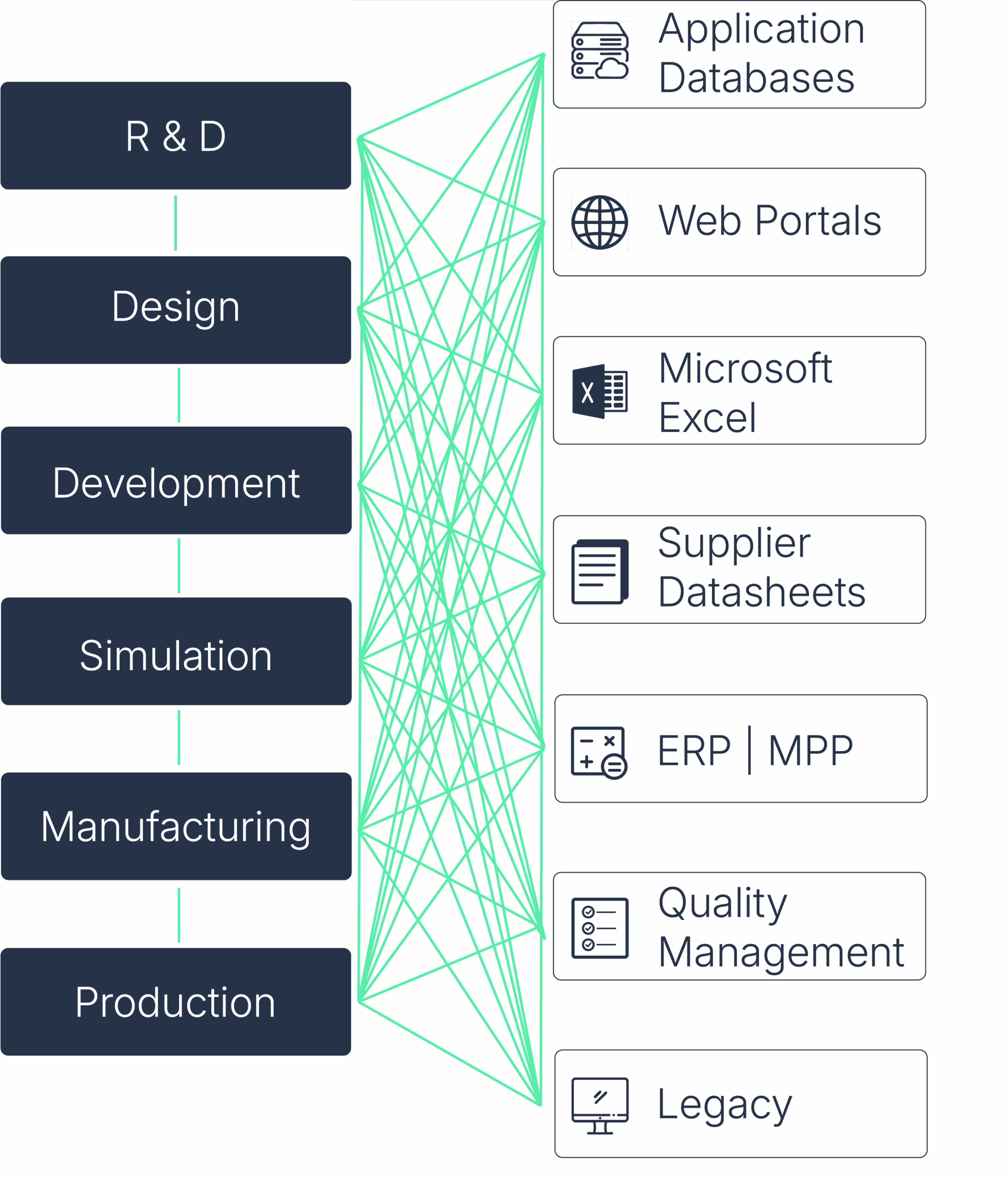

Leverage the potential of your materials: With Siemens Teamcenter IMM and our expertise, you take your material management to the next, digitalized level. We integrate centralized material management into your PLM system to build the digital material twin.

Manufacturing companies—whether in electronics, automotive, or mechanical engineering must efficiently manage, update, and align thousands of materials, components, and parts with regulatory requirements. This involves not only ensuring material compliance, but also increasingly integrating sustainability criteria into processes.

We Integrate Centralized Material Management into your PLM-System to Build the Digital Material Twin

"The selection of a material is no longer just a technical question, but often also a matter of procurement and sustainability. For example, anyone wanting to purchase a specific type of steel, whether for ecological or economic reasons, needs clean, consistent material management."

Till Gauger, Nexpirit PLM Solution Architect

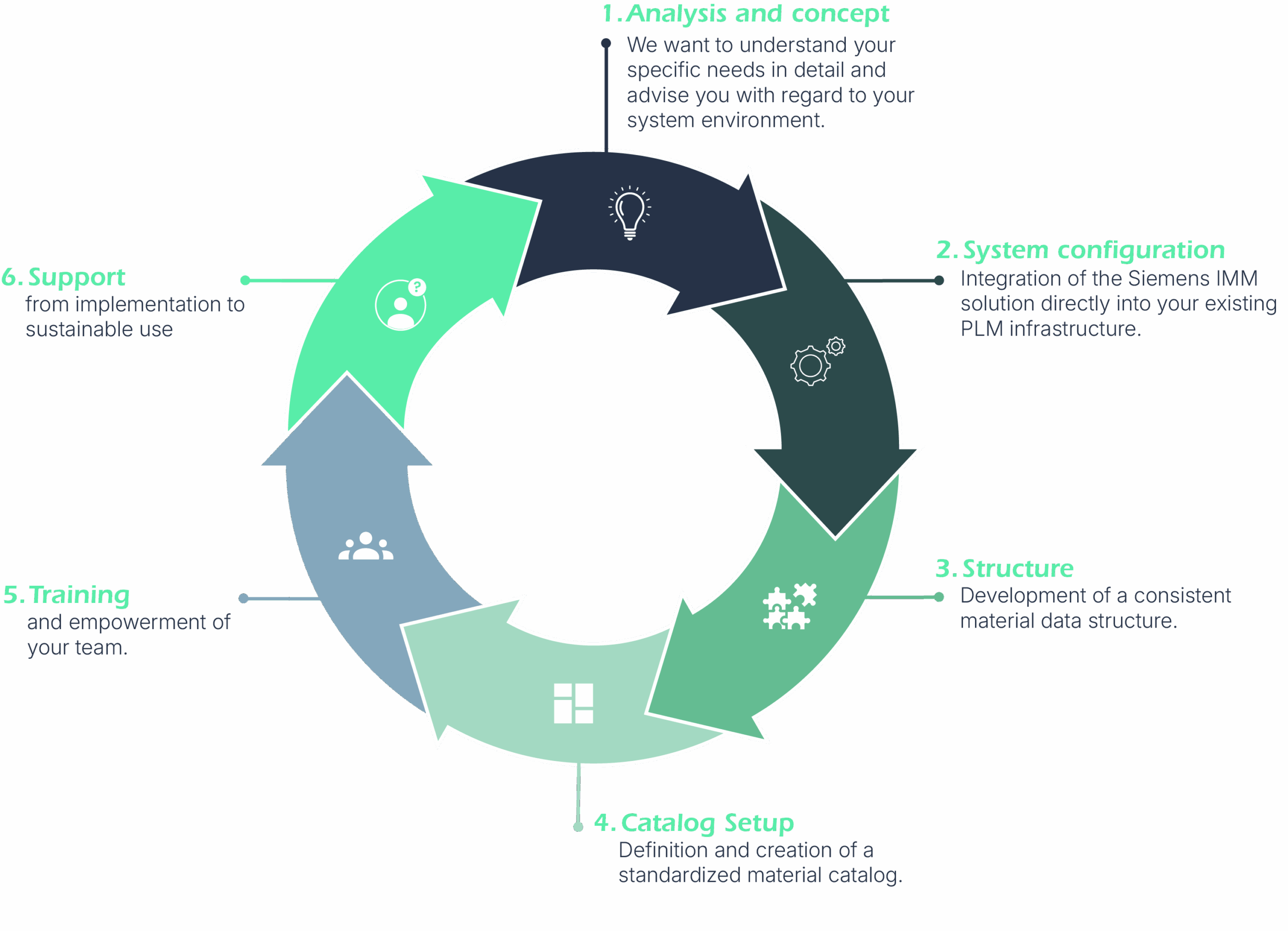

This is how your IMM integration works with Nexpirit

"A major advantage for GM is that materials can now be searched for, selected, and assigned based on the application or functional area.“

„The material management integrated into Teamcenter is the platform for standardizing raw material processes across the entire company and different business units. It enables control, transparency, and the exchange of information on all technical aspects of materials.“

„With a single source for material data, we now spend less time searching for the right materials. Our materials are now easily accessible and findable directly from the design and simulation tools.“

Integrated Material Management (IMM) provides a centralized, clearly structured database of your materials and bills of materials. It forms the foundation for all calculations, potential analyses, and assessments required for your Product Compliance and sustainability goals. The main advantages of IMM:

At Leica Geosystems, IMM paved the way for successful product and export compliance, creating the foundation for future sustainability initiatives.

Leica Geosystems, a company of the Hexagon Group, is a manufacturer of globally renowned, high-precision surveying technology.

Discover how Siemens Teamcenter IMM can advance your company – with Nexpirit as a strong implementation partner.

The digital material twin in Teamcenter® Integrated Material Management (IMM) is the central foundation for intelligent, end-to-end material data management. You benefit especially when all material information, from technical properties to environmental indicators, is consistent, up-to-date, and system-wide accessible.

By integrating into PLM, CAx, compliance, and sustainability systems, a unified data source is created that not only increases data quality but also automates processes. This enables materials to be efficiently assigned, compared, and validated.

The digital material twin thus becomes a strategic lever for well-informed decisions, reduced effort, and greater transparency throughout the entire product lifecycle.

“Single Source of Truth” in material management means that all relevant material data is maintained and managed in one central, reliable location within the system, ideally in a PLM system like Teamcenter®.

Instead of scattered information in Excel spreadsheets, across departments or system silos, a unified, version-controlled, and current data base is available.

This ensures clarity and consistency across all processes, from design to compliance to sustainability. Decisions can be made faster, redundancies are avoided, and sources of error are minimized.

The integrated material management (IMM) in Teamcenter® already provides critical material information early in the development process, covering substances, substance restrictions, recycling content, or emission values.

These data form the foundation for complying with regulations such as REACH, RoHS, TSCA & others. Thanks to direct links with bills of materials, CAD models, and compliance tools, compliance is already taken into account and systemically verified during the design phase.

IMM thus transforms regulatory requirements from an obstacle into an integrated part of future-proof product development.

With our newsletter, you’ll regularly receive insights, event tips, and expert articles directly in your inbox.

*By submitting the form, the data you provide will be processed by Nexpirit GmbH, Lohbach 8, 32457 Porta Westfalica, Germany, for the purpose of processing your enquiry(s). Your data will be processed strictly for the intended purpose. Further information on the processing of your data within our website can be found in our data protection information.